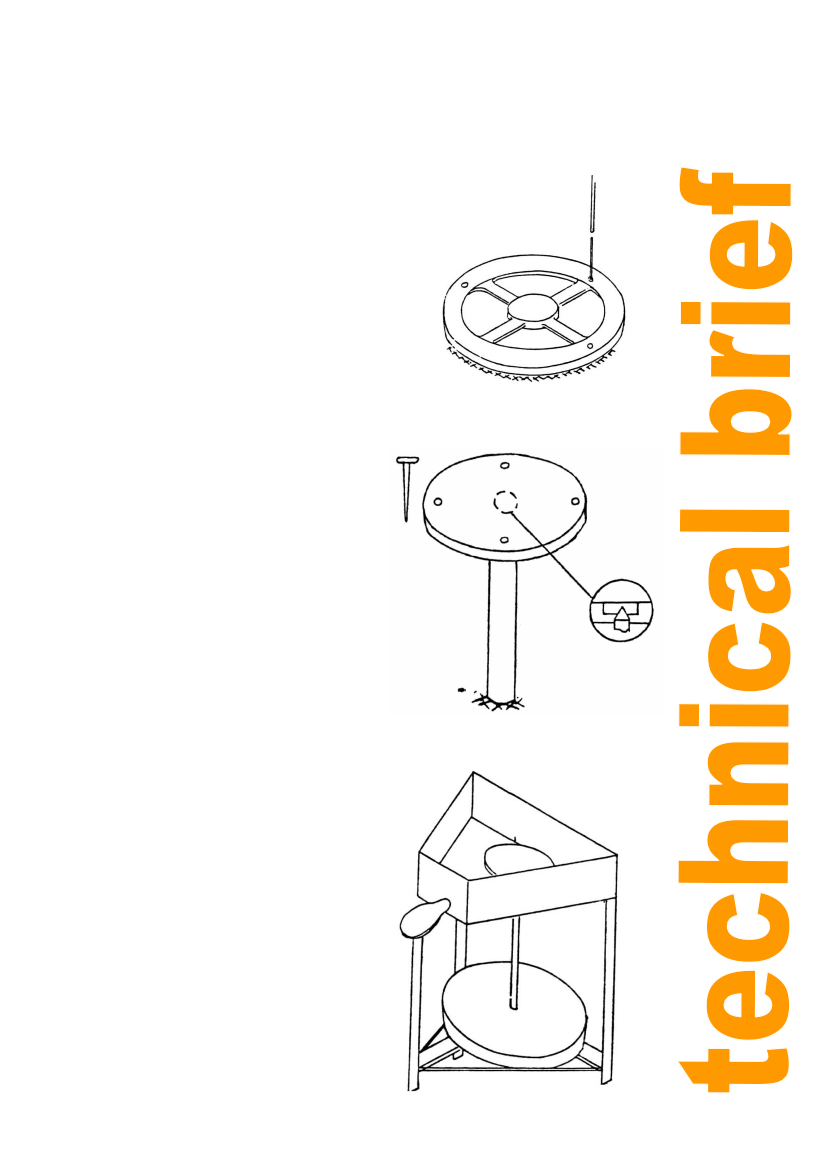

Modifications to a pottery wheel

Practical Action

Slip casting is similar to metal casting. Clay in liquid state (casting slip) is poured into a dry

Plaster of Paris mould in which the water of the clay paste is absorbed by the Plaster of Paris

leaving a coating of clay in the mould.

Pottery Wheels:

Potters are characterised by the throwing wheel they use

in the throwing process. Potters' wheels were recorded to

have been in existence in Central Asia by 3,500 B.C., in

Egypt by around 3,200 B.C., and in Crete 3,000 B.C. The

earliest form of the throwing wheel was a rough horizontal

circular table turned on a pivot very close to the ground.

Another variation was a wheel similar to a cartwheel (with

spokes) placed horizontally and turned on a pivot with the

help of a long pole inserted into a socket of the wheel

(figure 1) the Indian wheel.

Chinese/Japanese handwheels had a heavy wooden disc

mounted on a porcelain cup. The potter imparts energy to

the wheel by rotating the disc vigorously with the help of a

short stick inserted in a hole on the disc (figure 2) the

Chinese/Japanese handwheel.

Figure 1: Indian Wheel

An improvement to this wheel was made when the

work table was raised up to enable the potter to

sit comfortably at work, while he imparted

momentum to another wheel below, attached to

the work table, by kicking it (lower wheel) with his

foot. This kickwheel is sometimes referred to as

the German wheel (figure 3).

An attempt to transfer kicking of the wheel to a

pedal action was made in the St. Ives kickwheel.

In this wheel a cranked spindle connecting the

worktable to the inertia wheel was linked to a bar,

the kicking of which imparted rotary motion to the

inertia wheel (figure 4) St. Ives Kickwheel.

The modern potter's wheel has the drive through a

friction clutch connected to an electric motor.

The Criteria Demanded in the Modification:

The essential requirements of a potter's wheel

are:-

a flat circular disc to rotate about a

vertical axis forming a rotating worktable.

the worktable continuing to rotate while

the potter forms the article using his

hands, during which time his feet should

remain idle.

if any energy impartation is required from

the potter, it should be through the use of

his legs only.

The modification finally demanded a kickwheel

suitable for operation by rural female operators.

Figure 2: Chinese Handwheel

Figure 3: German Kickwheel

2